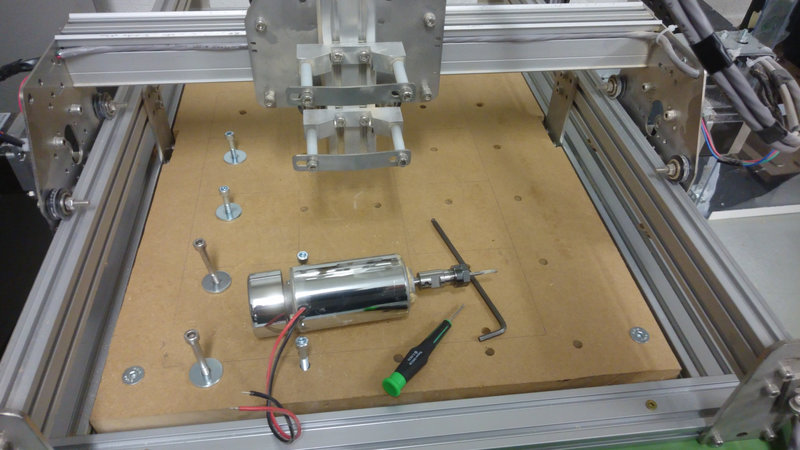

I choosed the small 300W @ 48V DC-spindle that I am using on my eShapeoko CNC-router on the basis of it is supposedly low level of noise. I was hoping to be able to use the router in my apartment and low noise was therefore very important.

The obvious drawback however with this small DC-spindle is that it is very low power. It needs to be run with a low feed and shallow depth pass to be able to handle the cutting load.

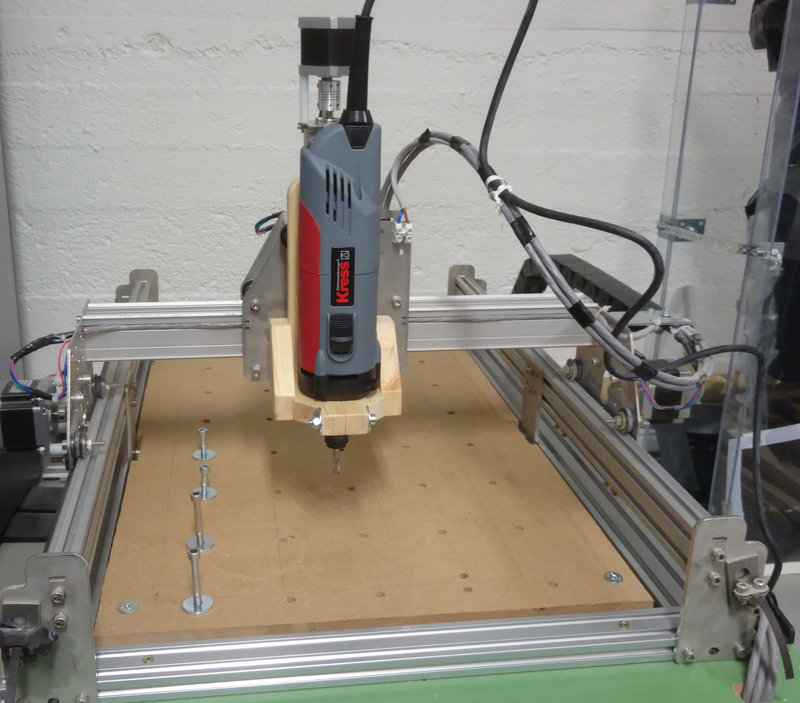

Since some months back my CNC-router is stationed at Devex workshop. There is no need for low noise in the workshop so I decided to upgrade the spindle to the high power Kress 1050 FME-1.

There is a substantial size difference as well.

The speed range is 5000-25000 RPM and the max power draw is 1050 W.

I can't use the same mount for the new Kress that I used for the old spindle. So I had to build a new one.

CNC Workflow, Design, LibreCAD, CamBam, Camotics

I manfactured all the parts for the mount using my CNC-router. My usual workflow and toolchain when using the CNC is consisting mostly of free and open-source software (FOSS). Here is a short summary of the toolchain.

First I draw the parts in a CAD software. In this case I use LibreCAD which is a 2D CAD software. The files are saved in DXF-format.

I could have used a 3D-cad software as well like FreeCAD for drawing the parts.

However in this case that would have been totally unneccessary since the geomtry of the parts are most easily described in 2D.

Then I need to create toolpaths for the router. For that I use the CAM software CamBam. With CamBam I can create G code (instructions) from the CAD file.

CamBam is unfortunately not FOSS but is a very good a and convinient software to use and license cost is reasonable.

A FOSS alternative is Cammill but it lacks some user friendliness compared to for example CamBam.

Before I run the gcode in the actual router it can be good to do a simulation in order to verify that the code do what it is intended to do. For that I use the FOSS simulation software Camotics.

Camotics is really easy to use and the resulting solid can be saved as a 3D-model for analyze in for example a third part program.

Manufacturing

The routing of the parts went straight forward. Each part took roughly 15 minutes to complete.

The mount is constructed from 18 mm glued fir-board. It is a simple L-shaped design with 45 degress trusses on both side to give a strong construction.

The parts are designed with grooves in order to simplify the assembly and make sure that everything is square.

I cut the holding tabs with a small cutter.

I cut the holding tabs with a small cutter.

I sanded all the parts.

I sanded all the parts.

The grooves can be seen in this picture.

The grooves can be seen in this picture.

Glueing the parts went relatively smooth but I have to sand some more to get the parts to fit.

Because of the grooves I only needed two clamps to hold everything in the right position.

To create the clamping mechanism for the spindle I made a cut with a saw.

I also drilled a hole perpendicular to the cut.

To create the clamping mechanism for the spindle I made a cut with a saw.

I also drilled a hole perpendicular to the cut.

Using a screw and a nut I could then clamp the spindle to the mount.

Using a screw and a nut I could then clamp the spindle to the mount.

Mounting

The DC-spindle is mounted using a simple clamping around the spindle body.

The DC-spindle is mounted using a simple clamping around the spindle body.

It is simple to remove.

It is simple to remove.

There are grooves for T-nuts in the aluminum profile that the Z axis is created from.

The new mount is mounted using M5 screws and such T-nuts.

Here is the new mount in place. It was a little fiddly but it was alright.

Here is the new mount in place. It was a little fiddly but it was alright.

And here is the Kress motor in place as well.

And here is the Kress motor in place as well.

Test routing

As a first test I created a small part for the turntable-project.

The results was very good. I was very supprised by the ease of the cut and how silent it actually was. The noise was much less irritating than the previous spindle.

I used the following settings when milling this part.

- Router bit: 6 mm two-flute carbide end mill

- Speed: 20000 rpm

- Depth pass: 2 mm

- Feed: 750 mm/min

This equals to roughly 5-6 times as high material removal rate than what I could achieve with the old setup.

The carbide router-bit from CNC-Plus was exceptionally good!

The carbide router-bit from CNC-Plus was exceptionally good!

Final thoughts

Using fir for the mount seems to have worked out okay but I think it wouldn't hurt using some kind of hardwood at least for the clamping part of the mount.

And finally I would really like to recommend the Kress 1050 FME-1 spindle, it is a really good and high quality spindle.