The turntable project is moving forward. Now the platter base is completed.

The base consists of four layers of 18 mm thick fir board. The profile for each layer is identical but the holes vary slightly.

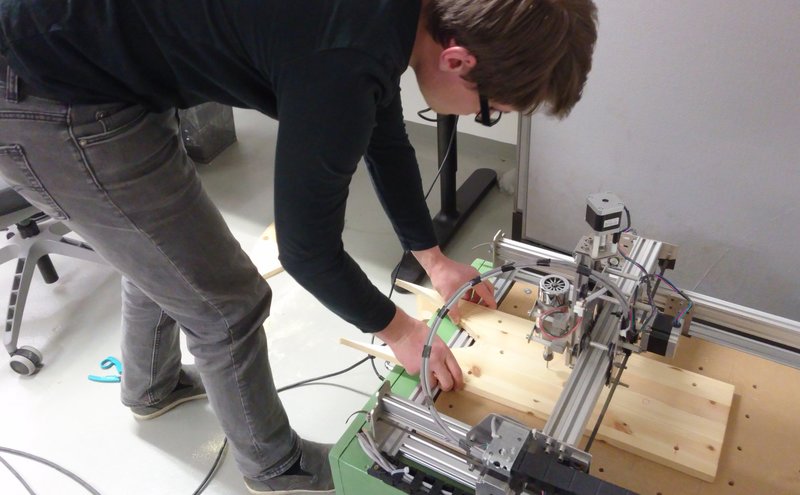

I aligned the stock material in the router and secured it with screws and big washers in all four corners.

First I routed all the holes and then the profile. The profile is cut with holding tabs to keep the piece from coming loose before the routing is completed.

The holding tabs can then easily be cut using a pliers.

I needed four layers so I had to keep measuring and routing. Each piece took about 45 minutes in the router.

For the routing I used a 3.125 mm straight two-flute endmill with 1 mm depth increment per pass and 500 mm/min feed in the X/Y-direction.

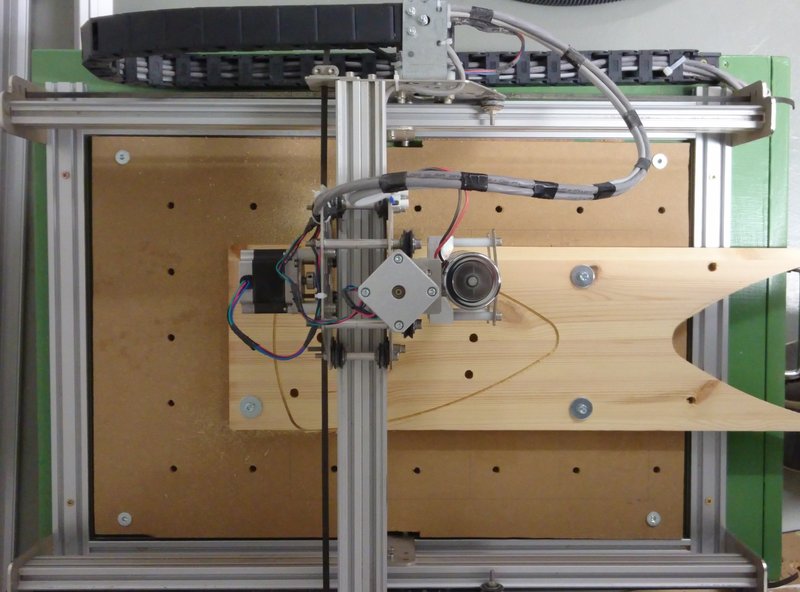

This is the finished pieces.

The layers where glued together and I forced the dowels in to place using a hand vice.

The protruding dowels were first cut with a saw and then filed flush using the flat side of the file.

It is incredible how good these kinds of files are for woodworking! I think they are underestimated and underused.

Here is a view from the top. As can be seen in the picture: Five holes are for driving wooden dowels through when gluing and fixating the layers. The big hole is for mounting the platter bearing. The two assymetrical holes in the top of the picture are for mounting the tonearm.

The next step in the projetct is to design the motor part of the turntable.